Description

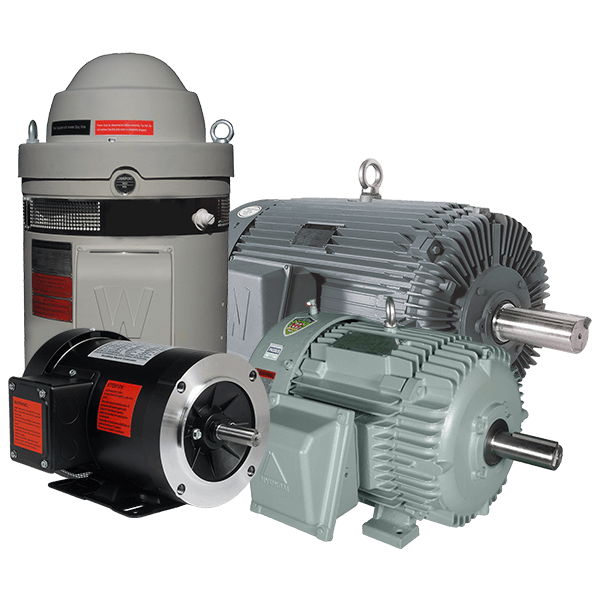

An electric motor is a device used to convert electricity into mechanical energy—opposite to an electric generator. They operate using principles of electromagnetism, which shows that a force is applied when an electric current is present in a magnetic field. This force creates a torque on a loop of wire present in the magnetic field, which causes the motor to spin and perform useful work. Motors are used in a wide range of applications, such as fans, power tools, appliances, electric vehicles, and hybrid cars.

Motors have many different working parts in order for them to continually rotate, providing power as needed. Motors can run off of direct current (DC) or alternating current (AC), and both have their benefits and drawbacks. For the purpose of this article a DC motor will be analyzed, to read about AC motors, click here.

The main parts of a DC motor include:

Stator: The stationary part of the motor, specifically the magnet. Electromagnets are often used in order to provide more power.

Rotor: The coil that is mounted on an axle and spins at high speeds, providing rotational mechanical energy to the system.

Commutator: Without it, the rotor would not be able to spin continuously due to opposing forces created by the changing current. The commutator allows the rotor to spin by reversing the current each time the coil does a half turn.

Power source: Supplies an electromotive force that causes current to flow in the system.

Brushes: These are connected to the terminals of the power source, allowing electric power to flow into the commutator.

- The applications of electrical motors mainly include blowers, fans, machine tools, pumps, turbines, power tools, alternators, compressors, rolling mills, ships, movers, paper mills.

- The electric motor is an essential device in different applications like HVAC- heating ventilating & cooling equipment, home appliances, and motor vehicles.

- Electric motors have several advantages whenever we compare with normal engines which include the following.

- The primary cost of these motors are low compared with the fossil fuel engines, but the horsepower rating of both are similar.

- These motors include moving parts, so the lifespan of these motors is longer.

- The capacity of these motors is up to 30,000 hrs as we maintained properly. So each motor requires little maintenance

- These motors are extremely efficient & automatic control permits for automatic-start & stop functions.

- These motors don’t use fuel because they don’t require the maintenance of engine oil, otherwise, battery service.

- The disadvantages of these motors include the following.

- Large electric motors are not easily movable, and consideration should be made for the exact voltage and current supply

- In some situations, expensive line expansions are mandatory for isolated areas where electrical power is not accessible.

- Usually, the performance of these motors is more efficient.

Application

The applications of electrical motors include the following.

Advantages of Electrical Motor

Disadvantages of Electric Motor

Technical Docs

Please feel free to contact us for any inquiries regarding this product. We can supply all brands, models/ types depending with your requirements.

Reviews

There are no reviews yet.