Description

A pneumatic actuator is a device that converts energy typically in the form of compressed air into mechanical motion. Within the industry, pneumatic actuators are recognised by several different names including pneumatic cylinders, air cylinders, and air actuators; all of which are one and the same.

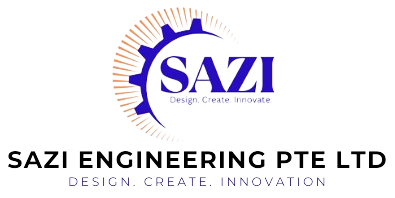

Consisting of a piston, cylinder, and valves or ports, a pneumatic actuator can convert energy into linear or rotary mechanical motions. This is dependent on whether the application is using a pneumatic rotary actuator or a linear actuator.

These include adjustable air cushions on both ends that slow cylinder speed at the end of stroke, reducing impact and extending cylinder life.

1. Rotary angle: 90o

2. Air supply pressure: 0.3~0.8MPa

3. Top connection: VDI/VDE3845 NAMUR

4. Bottom connection: ISO 5211 and DIN3337

Linear actuators are well suited for fitting to angle seat control valves built for high temperature and steam applications, whereas the pneumatic rotary actuators are better suited for fitting to quarter-turn valves depending on the specification of the application.

Application

There are many industries across the globe that will use pneumatic actuators to power their everyday essentials.

Water treatment plants

Water treatment plants, for example have 30% of their valves controlled by pneumatic systems. They are used within the instruments, sensors, valves, and filter membranes, too. With the vast real estate of water treatment plants, monitoring systems can slow the bandwidth, so using a compressed air module that can be monitored locally, is a benefit to the overall system.

Chemical and processes industries

Chemical and processes industries use the pneumatic actuators simply in valving to control the flow of chemicals. As these industries often perform dangerous tasks such as handling hazardous or even toxic chemicals, the pneumatic actuators are commonly used to ensure safety and reliability. As mentioned above, their benefits include their ability to withstand high temperatures and durability. That’s why these are a common choice within gas, steam and thermal power plants.

Manufacturing industry

While it is a broad spectrum of processes, there will almost always be space for a pneumatic actuator in the manufacturing industry. They’re used within manufacturing due to their durability and low-maintenance needs. As a manufacturing plant is large, owners require moving parts that will last a long time without the need of topping up or maintenance which are needed with the hydraulic and electric systems.

Food handling industry

With hydraulic fluid or electricity, the chance of leaking and contaminating the food is much higher than the chance of compressed gas leaking and causing slowed manufacturing. With food it can be imperative to have durable actuators that will cause food contamination or cause sparks. This is why much of the food processing industry will make use of the pneumatic systems.

Electronic Industry

Handling, assembling and testing small parts are at the heart of the electronics industry. Production and assembly of electronic components such as semiconductors is fast-paced and requires precision. With a pneumatic system in place, it is capable of high-speed and accurate positioning, despite the high moving mass. As the product cycles in the electronic industry is becoming ever shorter, pneumatic also provides a more economical solution in the long term than its hydraulic counterpart.

Technical Docs

Please feel free to contact us for any inquiries regarding this product. We can supply all brands, models/ types depending with your requirements.

Reviews

There are no reviews yet.